20/01/23

Special applications

Scrubbers

RCM scrubber-dryers remove any kind of dirt by means of brushes and detergent, leaving the floor perfectly clean.

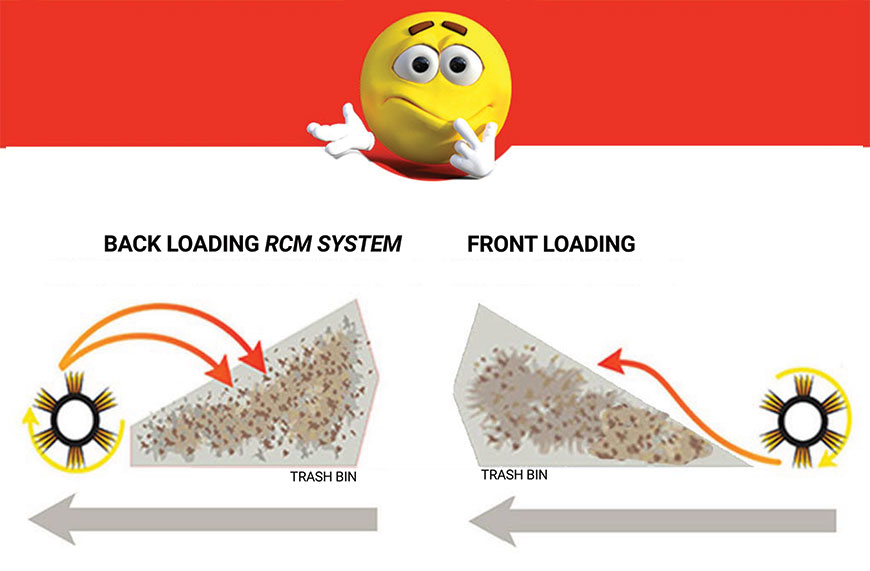

Sweepers

RCM sweepers collect any type of waste and thanks to their DUST BUSTER exclusive system they retain the finest particles leaving the area perfectly clean.

Combined

RCM combined machines can simultaneously collect the debris and wash using a detergent solution, leaving the floor completely dry.

Vacuum cleaners

RCM vacuum cleaners are designed to remove the dust and small debris from corners, interstices and surfaces that cannot be reached by other machines.

Single disk machine

RCM single brushes are suitable for washing or perform specific actions (spray cleaning, burnishing, etc.) on surfaces.

Sanitizing scrubbers

SANITIZING scrubbers grant daily a fast, economical and easy cleaning and disinfection operation keeping every working environment safe.

Ozone scrubbers

ECO3 Sanitizing scrubber-dryers are perfect for professional sanitization of different types of floors. They use the ozone oxidation process and do not require chemical sanitizing products.

Stainless steel scrubbers

RCM stainless steel scrubber-dryers can be used in environments with highly corrosive substances.

Scrubbers for steep gradients

The machines featuring special drive are designed to easily overcome steep gradients even during operation.

Carpet cleaning

An innovative solution for maintenance cleaning of carpets (felt) using a sweeper and a scrubber.

Cleaning synthetic turfs

The RCM sweeper is suitable for the daily maintenance of synthetic turfs.

Urban micro cleaning

The RCM sweeper that collects the dirt and retains the dust generated by daily life.

Street sweepers

Detergents